Diy » Custom 19 inch rack cabinet

This is the rack cabinet i made for my a/v and network equipment. The cabinet is 75.5”H x 20.5”W x 19”D and consist of 3 sections, the 2 upper sections are 19-1/8” wide rack mount space and the lower section is a 16” height compartment to store my UPS. There are 18 units of rack space in the middle section and 12 units in the upper section.

Design

Rack space

This rack is obviously not designed to fit a standard server chassis. The 18U section has a depth clearance of 16-3/8” and the 12U section, 13-9/16” which is enough to accommodate most small server chassis (mini-itx).

Ventilation

The equipment mounted in this rack produce very little to no heat so i do not need forced air cooling. The opening at the back and the 1U vent panels at the front are more than enough to keep everything cool. You could cut holes at the top and upper shelf and install 120mm fans.

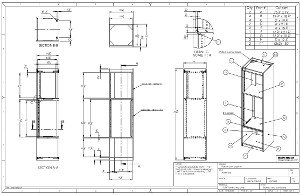

Drawings

Here are the drawings of my rack (PDF) :

Construction

Rack rails

I bought 4 18U “L” steel rack rails on Ebay and used two of them as is and cut the others to size (12U). I designed the cabinet so that the opening is exactly 19-1/8” wide. This gives 1/16” wiggle room on each side. Power rails and cable management

Power distribution

I wanted to add a power strip on each side but did not find any that were the length I needed nor one that was reasonably priced, so i went with the poor man’s solution instead. I installed three power strip : two for the a/v equipment and one for network.

There are two 1.5”W x 1.5”D wire duct on each side of the middle section and 1.25”W x 1”D (white) on each side in the upper section and at the top and bottom of the middle section.

Rackmount cable organiser

I also used the left over wire duct to make a rackmount cable organizer. I used a 1U blank panel and attached the wire duct on the back side of the panel and cut openings on each side for the wires.

Material

I Used 11/16” laminated pine sheets. They are 2 inch strips of solid pine glued together to form a 8 by 4 feet panel. That was the cheapest (after melamine) that I could find at my local hardware store. You can easily see the individual strips but once they are properly sanded, stained and varnished, they don’t look too bad. However, the sides which are cut against the grain are less pretty. To hide them, I applied a 3/4 inch iron-on pine veneer strip on the edges and trimmed the excess.

The parts are joined together with glued wooden dowels (5/16”) and steel corner braces on top and bottom of the rack (see the drawings).

Finishing

Because pine tends to not absorb stain evenly, you should use a pre-stain conditioner (minwax) before applying the stain. You should always use a conditioner even if you intend to paint it black otherwise it will look like crap!